Laminating Skills

The importance of chamfering and layering. Whenever we remove fibreglass material, we need to replace it in a way, so the new layers overlap each other. When doing a multi-layer repair lamination, the first layer applied must be the smallest unless otherwise stated in the work instructions. The size of the overlaps are determined by the size of the repair and the requirements within the work instructions.

The strength of the repair depends on each layer of fibres overlapping the corresponding layers to ensure correct load transfer through the repair. The amount of overlaps or chamfers is determined by the amount of layers that have been removed. For example; if you are repairing a damage that is three layers deep then you will have three chamfer steps out from the deepest point.

In cases where the glass overlaps are not specified, a minimum for lamination will be around 5% of the glass weight per a metre squared in millimetres (for example 600gsm glass fibre ≈ 30mm overlap on good material). Below is a table showing how the size of overlaps can be calculated. NB: Overlaps will vary depending on the blade manufacturer and design. Always refer to work instructions for calculations.

Fibre Orientation The direction of the replacement fibres is vitally important. They must corespond with the existing fibres to ensure correct load transfer through the repair. Incorrect lay-up of fibres can cause further damage when the turbine is in operation. Avoid using fibres with any kinks or bends.

Dry Fibres and air voids Very important to ensure the fibres are wetted out properly. Too little resin in the lamination will leave dry fibres resulting in a weak repair. Too much resin will leave the repair area brittle and overweight. A strong lamination will contain roughly 60% fibres to 40% resin (matrix material)

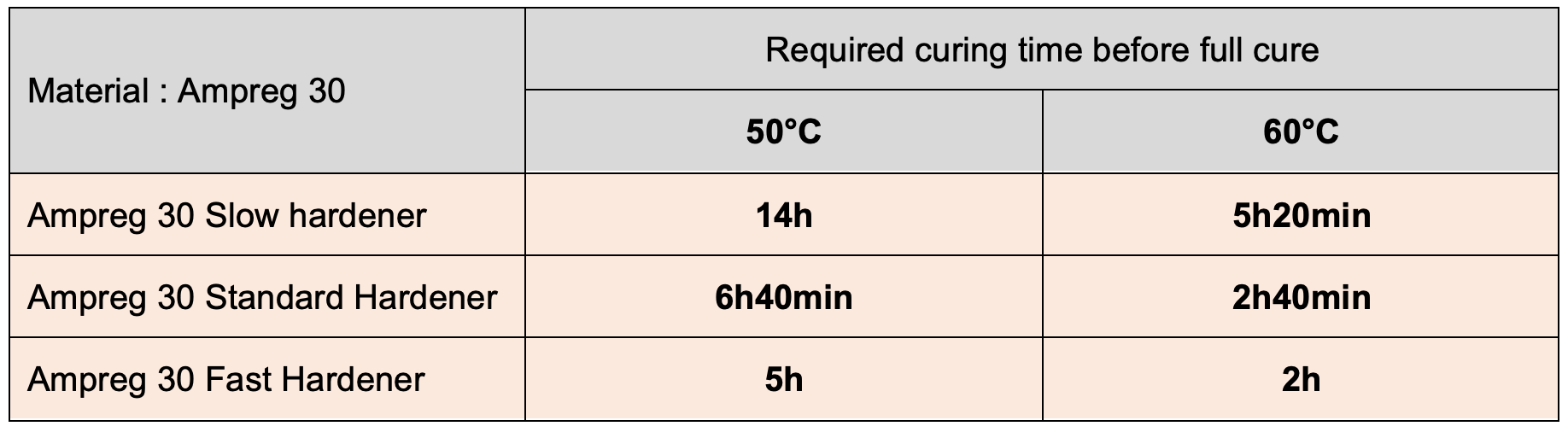

Curing of Laminations Ambient temperature curing of most epoxy resins is not allowed in blade repair as it is not fully cured without applying further heat. This is often done using a heat blanket on the repair. The amount of heat needed (post cure) is determined by the brand of resin used. Example below is using Ampreg 30 laminating resin.

If heat is applied to a curing material (such as using a heating blanket), it is recommended that it must be applied only once the material has gelled at room temperature, or even better, when it is tack-free.